Few would argue that it is more of a challenging task to correctly calibrate a vineyard sprayer than a broadacre sprayer. There is much to consider here but for vineyard application, one can note:

- Type of equipment (airblast versus airshear)

- Row and vine spacing, canopy height and trellising system

- Table versus wine grapes

- Contact versus systemic chemistry

- Seasonal effects and weather at the time of application

- Which convention to follow in order to determine the dilute volume required for a particular vine canopy

The Australian Wine Research Institute (AWRI) (1) states, “The water volume that produces coverage to the ‘point of runoff’ (where the vine canopy is thoroughly wet) is termed the dilute volume . This spray volume is the key to determining the amount of chemical that should be applied to a vine canopy to deposit a lethal dose. The label RATE /100 litres in conjunction with the dilute volume determines the amount of product that must be applied to a particular canopy whether dilute or concentrate spraying.”

The AWRI (1) in 2010 goes on to say that “Currently there are four options for determining the dilute volume required for a particular vine canopy:

- Measure in-field dilute volumes by test spraying to run-off

- Use estimates based on past experiences or regional best practice for similar situations

- Use Vine-Row-Volume methods such as Unit Canopy Row (UCR) to give you starting points

- Follow pre-existing Avcare recommendations.” (now CropLife)

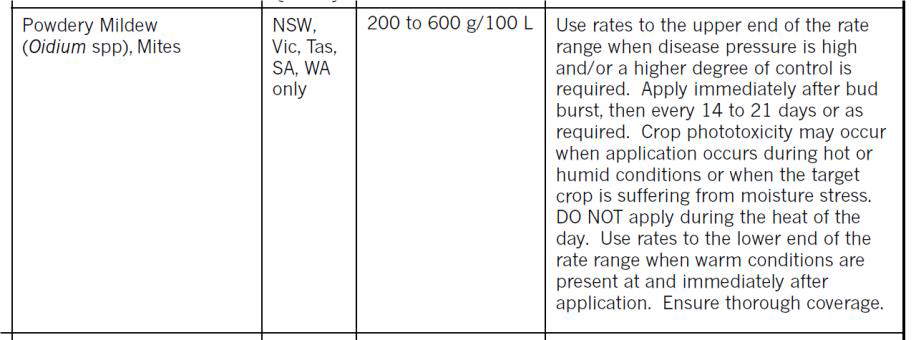

Talking to Scott Matthew, Syngenta’s Senior Technical Lead – Viticulture, he, like AWRI in their studies, found that in field measurement of dilute volumes as per the first dot point is also yielding great results with Syngenta’s suite of fungicide products. Scott’s description of the point of run-off references the inside of the vine canopy (or the targeted spray area, if in fact, you are looking to control powdery mildew, your dilute volume must be worked out as point of run-off inside the canopy) and relates to the coalescence of spray droplets on the leaf or fruit surface.

Some of Scott’s tips for efficacious vineyard spray application (focus on powdery mildew) include:

- The quantity or dose on the surface of the leaf, needed for an acceptable disease control, which for grapevines is worked out as a rate per 100L of water applied to the point of run-off

- The % of leaf area to be covered in order to achieve control, the 5 of leaf covered needs to be higher for protectant fungicides than for systemic (xylem mobile) fungicide.

- The thickness of the spray droplet residue (particularly for protectant fungicides like mancozeb and copper) must be durable enough to persist up to the next treatment given the breakdown by rain, wind, and UV light etc., 2010/11 estimates showed copper was only lasting 3-5 days

- Identifying the Target – There are two spray targets we need to identify. Firstly the biological target (the pest that is to be controlled) and application target (a place where the pesticide spray must be deposited in order for it to work on the biological target for effective control)

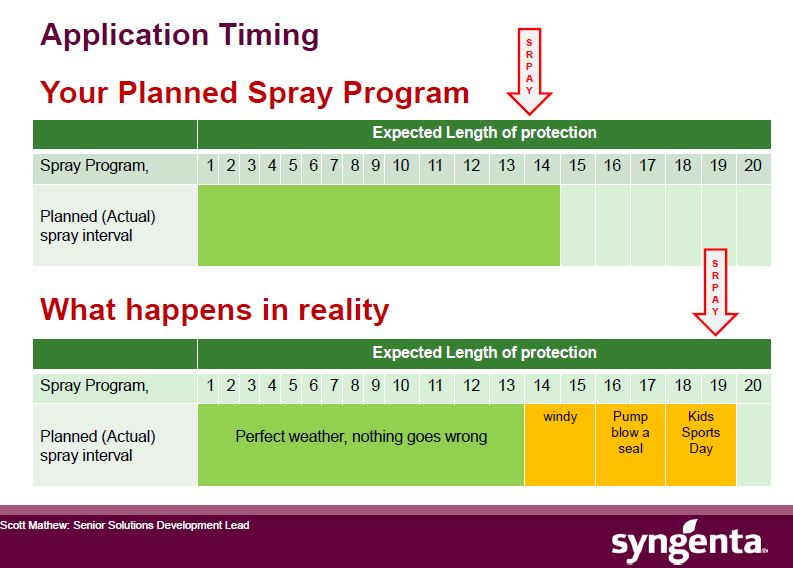

- Application timing – Slide 1 below shows what often happens in reality as opposed to what is ideal application timing

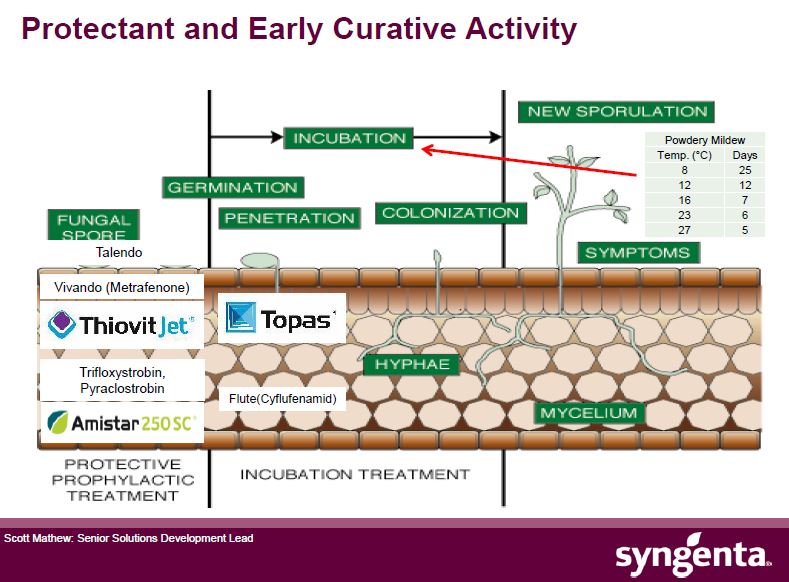

• Protectant (Preventative) Fungicide (PF) versus Curative Fungicide Activity (CF) – Slide 2, PF’s are applied before the development of disease and prevent spore germination or penetration of the pathogen into the plant whereas CF’s are applied when the disease is already present, but symptoms are not yet visible. Note from slide 2 that powdery mildew takes only 6 days for incubation at 23 degrees Celsius.

• Protectant (Preventative) Fungicide (PF) versus Curative Fungicide Activity (CF) – Slide 2, PF’s are applied before the development of disease and prevent spore germination or penetration of the pathogen into the plant whereas CF’s are applied when the disease is already present, but symptoms are not yet visible. Note from slide 2 that powdery mildew takes only 6 days for incubation at 23 degrees Celsius.  Factors affecting Spray Application

Factors affecting Spray Application

- Always check the product label for the Rainfast Period but as a general rule 2 –3 hours without rain after an application is needed for systemic fungicides to penetrate the leaf tissues as well as for protectant fungicides to stick to leaf surfaces

- Delta T, try and spray during Delta T values of 2 to 10 degrees Celsius to keep evaporation rates as low as possible given active ingredients, in their dry crystalline form, cannot move into the plant, note:

- A 50μm droplet will evaporate over 250 times quicker than a 200μm droplet

- On a hot day, a 50μm droplet may only travel 0.1 to 1m before it disappears while the 200μ and larger droplets have little to no chance of evaporating before reaching its target

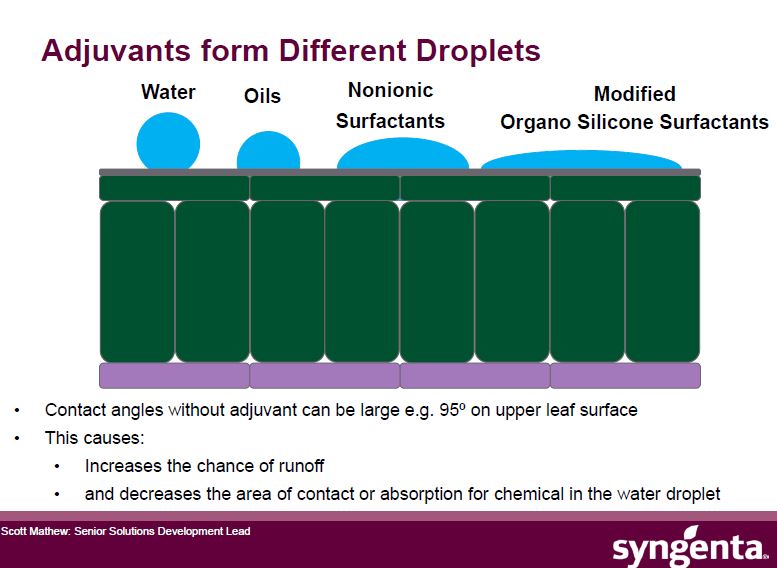

- Adjuvants – Should only be used if directed to do so by the label

- Follow product label guidance on water quality (check hardness, pH, dissolved salts or solids like silt and clay etc.) as well as mixing order

- Check your spray distribution with water sensitive paper, looking for good even coverage

Good coverage as shown on water sensitive paper

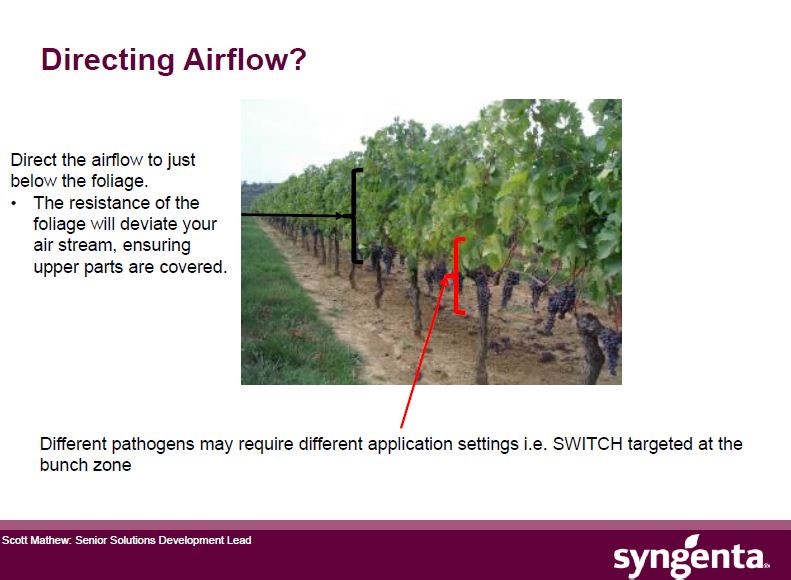

Good coverage as shown on water sensitive paper - Calibration and Direction of airflow (See diagram below)

- Getting the spray on your target

- Ensuring sufficient and thorough coverage

- Applying spray without environmental damage of non-target areas

- Targeting specific section of the crop

- Product labels – Have changed or are in process of change from litres per hectare to dilute rates per 100 litres of water and maximum concentration factors.

- Point of run-off: The amount of water required to wet the plant to the point where some spray droplets join together just before they run off the foliage or bunches

Objectives:

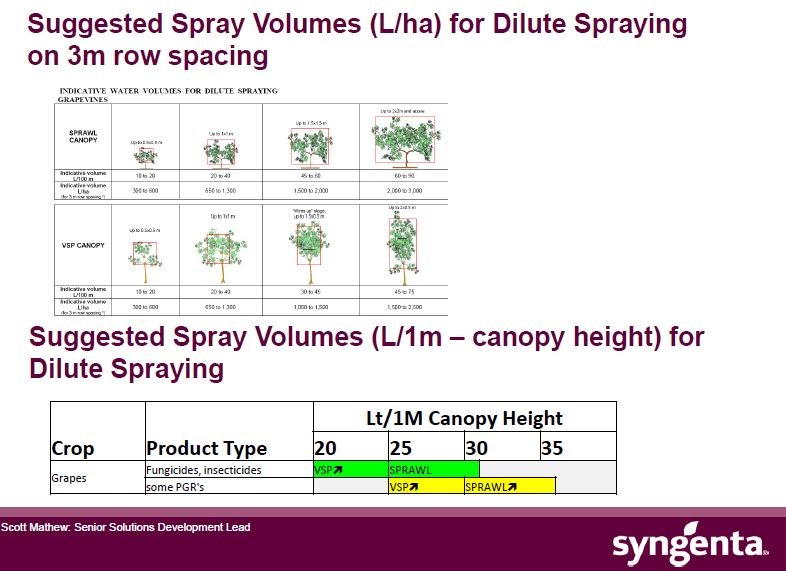

Dilute Spraying is Using any sprayer set up to apply volumes of water up to the point of runoff and matched to the crop being sprayed.

YOU MUST GET OUT IN THE VINEYARD and apply different test volumes at least 3 key times a season (also reference industry guidelines and expert advice). How do you work this out?  Dilute Spraying 1.Water volume to reach point of RUN-OFF = 36Lt/100m Number of rows/ha = 100 (1 Ha = 10,000m 2 3m (row width) = 33.33 Water volume/ha: 33.33 x 36 = 1199.8 L/ha (1200) 2. THIOVIT JET rate is 400g/100L 1200 L/100 = 12 (lots of 100L) 3. 400g X 12 = 4800g/ha

Dilute Spraying 1.Water volume to reach point of RUN-OFF = 36Lt/100m Number of rows/ha = 100 (1 Ha = 10,000m 2 3m (row width) = 33.33 Water volume/ha: 33.33 x 36 = 1199.8 L/ha (1200) 2. THIOVIT JET rate is 400g/100L 1200 L/100 = 12 (lots of 100L) 3. 400g X 12 = 4800g/ha  Note: The required dilute spray volume will change and the sprayer set up and operation may also need to be changed as the crop grows. Concentrated Spraying 1. Water volume to reach the point of RUN-OFF is 36Lt/100m 2. Your chosen spray volume is 18L/100m or 599.94Lt/ha 3. Your Concentration Factor (CF) is Dilute Volume (1200)/ Chosen Volume (600) = 2 4. The dilute application rate for THIOVIT JET rate is 400g/100L 5. The application rate for concentrate spraying = 400g X 2 (CF) = 800g/100L 6. The application rate/ha = 600/100 = 6 (lots of 100L) 800 X 6 =4800g/ha Watch out issues when determining test volumes at the point of runoff: 1. Leaves near the sprayer will usually reach the point of runoff before the inner canopy. 2. Runoff has not been achieved if the spay is dripping off the outer leaves but the inside of the canopy is mostly dry. 1. https://www.awri.com.au/wp-content/uploads/spray_dilute_volumes.pdf

Note: The required dilute spray volume will change and the sprayer set up and operation may also need to be changed as the crop grows. Concentrated Spraying 1. Water volume to reach the point of RUN-OFF is 36Lt/100m 2. Your chosen spray volume is 18L/100m or 599.94Lt/ha 3. Your Concentration Factor (CF) is Dilute Volume (1200)/ Chosen Volume (600) = 2 4. The dilute application rate for THIOVIT JET rate is 400g/100L 5. The application rate for concentrate spraying = 400g X 2 (CF) = 800g/100L 6. The application rate/ha = 600/100 = 6 (lots of 100L) 800 X 6 =4800g/ha Watch out issues when determining test volumes at the point of runoff: 1. Leaves near the sprayer will usually reach the point of runoff before the inner canopy. 2. Runoff has not been achieved if the spay is dripping off the outer leaves but the inside of the canopy is mostly dry. 1. https://www.awri.com.au/wp-content/uploads/spray_dilute_volumes.pdf