☐ Pre-operational check carried out on a clean sprayer with fresh water and a pre-season calibration performed to ensure correct application rates as well as proper machine function.

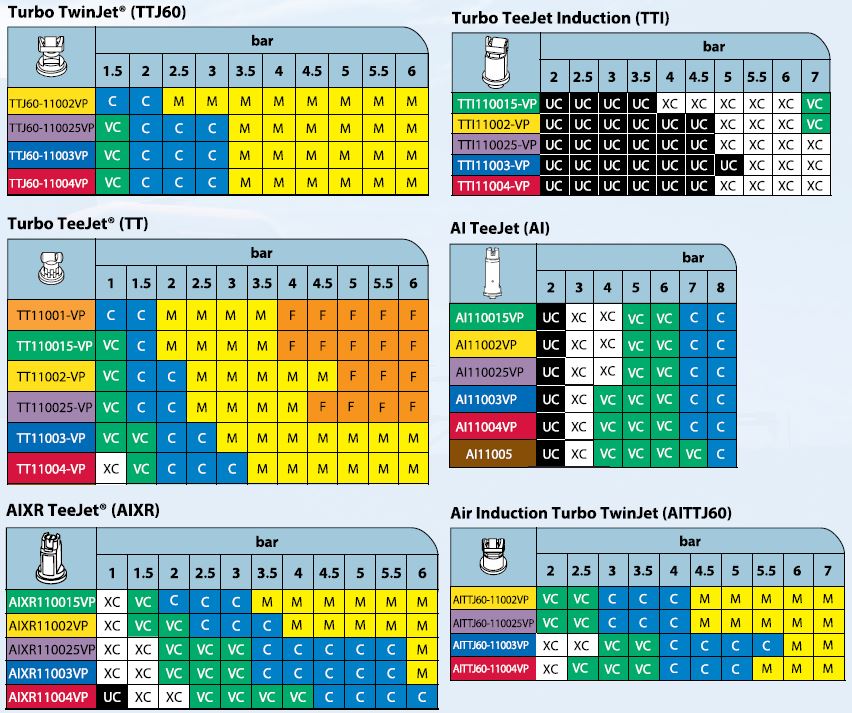

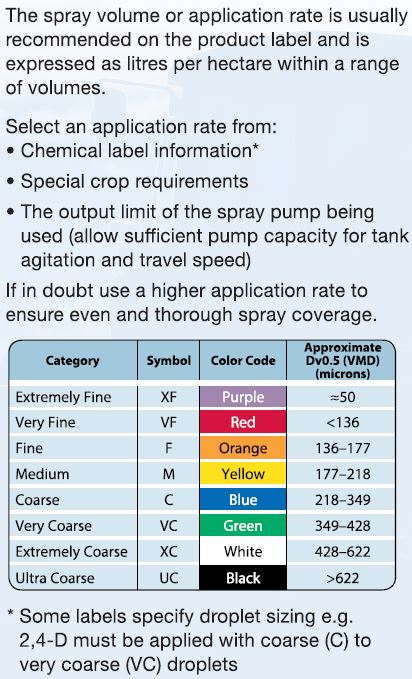

☐ Product labels checked especially the “Spray drift Restraints” and Mandated Spray Quality , Weather Conditions and Downwind No-Spray/Buffer Zones . Note the updated spray quality charts below for a selection of Teejet nozzles reflecting the new ASABE S572.1 standard (Figure 1).

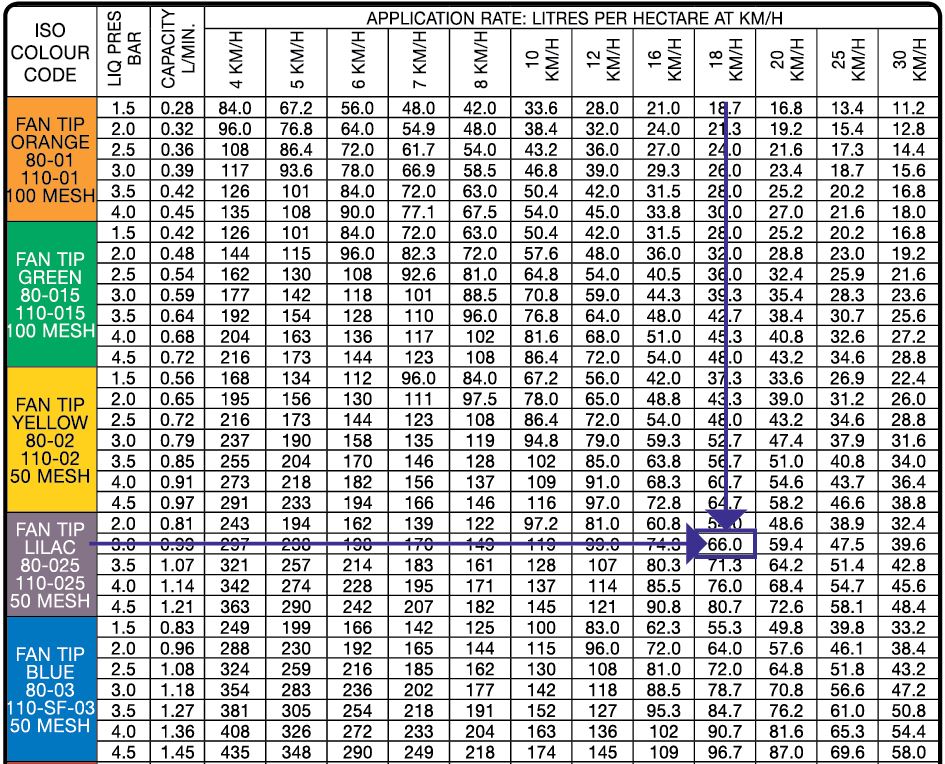

☐ My spray nozzles can produce the required spray quality requirements at the range of operating pressures produced for the application volumes and spraying speeds I use (i.e. Coarse as a minimum) for example a Teejet AIXR110025 Very Coarse at 3 bar and 66 L/ha water rate @at18 Km/h at 50 cm nozzle spacing.

☐ Boom height set at no higher than 50 cms above weed, stubble or crop canopy for 110-degree nozzles.

☐ Travel speed set to a maximum of 18 to 20 km/h to minimise pitching and yawing of boom (see Original Equipment Manufacturer specifications to see if faster speeds are allowed or covered by warranty with auto levelling capabilities and self-propelled sprayers).

☐ Weather forecasts checked – Met-Eye, Nufarm “SprayWise Decisions” and “Syngenta Weather”.

☐ No surface temperature inversions present at start of spraying, daytime windspeeds between 3 and 15 to 20 km/h and blowing away from sensitive areas and susceptible plants and crops (check Cottonmap.com.au for cotton plantings, also note the locations of vineyards, canola, tomato crops etc. downwind as part of awareness zones). At night it is suggested that windspeeds should be above 11-12 km/h to avoid inversion conditions.

☐ Record weather details (windspeed and direction, relative humidity and temperature) at start and finish of spraying and at each tank fill in between, monitoring weather for changes during the application. Keep an eye out for fog, dew, frost, smoke or dust hanging in the air and moving horizontally, and/or the flattening of clouds as the evening approaches as signs of inversion conditions.

☐ Ensure state training and application recording requirements are met for herbicide application (make within 24 to 48 hours of application and keep for at least 2 years).

☐ Flush tank and spray-lines with 2 % household ammonia, agitate well and let stand in sprayer overnight. Flush and rinse with clean water thoroughly before further use (2,4D amines).

Figure 1. Key Teejet nozzle Spray Quality (New ASABE S572.1 with a 40 dynes/cm adjuvant to better mimic a tank mix).

Figure 2. Spray nozzle flow chart showing an 025 at 3 bar and 18km/h highlighted.