Almost a decade of training chemical users across Australia, as well as 20 years as a grazier, provides you with some insight into the hazards of mixing chemical concentrates.

Some experiences that come to mind go back a fair way to the days of the organochlorines like dieldrin, endosulfan, chlordane etc. and often relate to application exposure rather than acute effects as a result of a splash or a spill (or inhalation of powders) during mixing.

However two instances that do stand out during mixing are a guy with skin burns to the stomach from hydrated lime contact and a young guy with permanent corneal injury to the eye from a corrosive paraquat formulation when he tipped the concentrated product into the spray tank without goggles or a face mask and copped some in one of his eyes, a very preventable event with the appropriate controls.

Hierarchy of controls

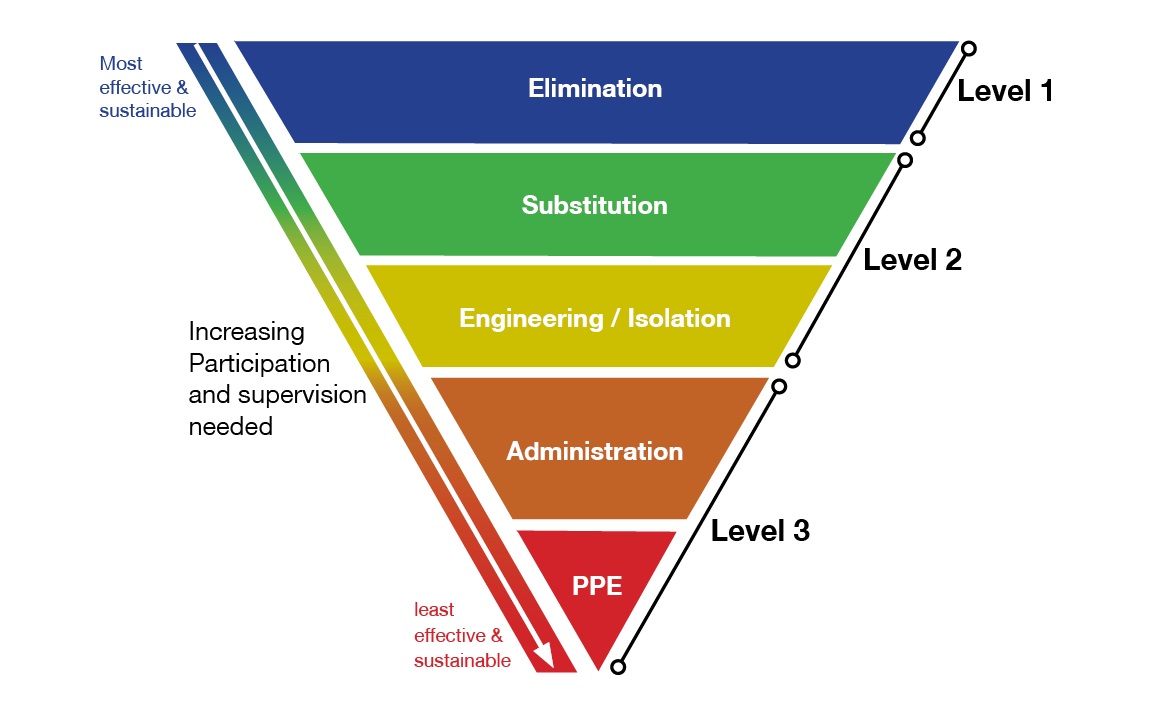

The hierarchy of controls is a system used in the workplace to minimise or eliminate exposure to hazards, and under WHS legislation a level 1 control would be to eliminate the hazard altogether, or if this was not possible, to reduce as many of the risks associated with hazard.

Regarding chemical mixing and use, this article will focus on reducing exposure as a key means of preventing harm or injury given that the need to apply chemical has been appropriately determined.

Figure 1. The Hierarchy of Controls

Top 10 tips for reducing exposure:

- Reduce the frequency of chemical use through the adoption of integrated non chemical control when feasible and as part of an IPM strategy

- Use closed caption delivery systems to pump chemical straight from drum into spray tank (see figure 2 for an example of closed caption delivery system)

- Training , SWMS (Safe Work Method Statements) or SOPS (Standard Operating Procedures) – Ensure all new workers are properly trained in chemical use and inducted into safe mixing and loading of chemicals prior to taking on such tasks for the first time. Never lift mixing jug above shoulder height, replace jugs if showing signs of UV degradation and cracks around the handle, place gently on mixing table when containing chemical and don’t mix in confined spaces without adequate ventilation

- Store chemicals safely and securely within easy reach of workers and with clear access to racking

- Do not remove labels from containers , replace if peeling off from drum. Never sniff contents to determine chemical enclosed, ensuring intact labels removes this issue from arising

- DO NOT decant pesticide into food or beverage containers

- Keep ignition sources well away from chemicals

- Always wash hands after mixing and before eating or drinking and clean up spills as per section 6 of the spilt products SDS

- Read the label Safety Directions for appropriate personal protection equipment (PPE) and wear it. Add a chemical mixing apron (chemical will soak through cotton work clothes instantly) and safety glasses to the list to protect key areas (note high absorption rates in figure 3 into eyes and groin areas (12 x that of the forearm)

- Make sure appropriate PPE is fitted, used and maintained properly and stored in a separate location to the chemicals. Chemical soiled PPE is of little or no benefit, at worst an even greater hazard, i.e. as with soiled gloves given your hands are in an occluded space with high levels of absorption, and don’t use liners unless medically advised to do so.

Figure 2. Shurflo Agrunner pump and flow meter

Figure 2. Shurflo Agrunner pump and flow meter

Figure 3. Chemical absorption rates relative to the forearm

Figure 3. Chemical absorption rates relative to the forearm

Always remember that mixing hazardous chemicals in concentrated form is often one of the more dangerous tasks when applying chemicals.

In summary note that the tips to reduce chemical exposure when mixing starts at the widest part of the hierarchy of control triangle and works down to the pointy end, finishing with PPE, the last line of defense. If you use an engineering/isolation control like a closed caption transfer pump or an administration control such as a standard operating procedure of never lifting a jug of chemical concentrate above your shoulders, the potential for harmful contact is greatly reduced. PPE of course has its place, because hoses can fatigue and burst under pressure, but it has to be well maintained, the correct size and fit for the user and appropriate to the chemical/s used and task in hand.

The dichotomy of pesticide use is that although WHS concerns are paramount, a layer of complexity can be added whereby a substitution control from a scheduled S7 Dangerous Poison to a S5 poison of lower toxicity, i.e. with councils favouring glyphosate over paraquat for WHS reasons (staff and public bystanders) increases the selection pressures for weed resistance to glyphosate over time.